Innovative Approaches to Reduce Friction and Enhance Performance

The Power of Minimal Quantity Lubrication (MQL)

Revolutionary Strategies for Enhanced Lubrication Efficiency

Minimal Quantity Lubrication (MQL) has emerged as a game-changing technique in the field of lubrication, offering numerous benefits over traditional methods. By significantly reducing the amount of lubricant used during machining processes, MQL not only minimizes waste but also enhances overall performance. This cutting-edge approach optimizes lubricant application by delivering precise quantities directly to the contact zone between tool and workpiece, resulting in reduced friction and improved surface quality.

Achieving Superior Machining Results through MQL Implementation

Elevating Precision and Sustainability in Manufacturing Practices

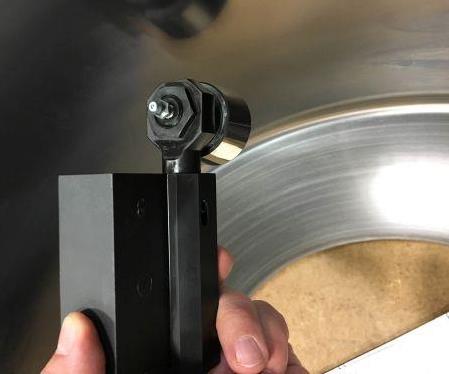

Implementing MQL techniques enables manufacturers to achieve superior results while prioritizing sustainability. By utilizing advanced nozzle systems that deliver minute amounts of lubricant at high pressure, this method ensures efficient coverage precisely where it is needed most. The controlled delivery mechanism reduces excess oil consumption, leading to cost savings and environmental benefits. Moreover, the targeted application allows for better chip evacuation during machining operations, preventing clogging or damage caused by excessive coolant accumulation.

Unleashing Potential: Advantages Beyond Traditional Methods

Redefining Industry Standards with Cutting-Edge Innovations

The advantages offered by MQL extend beyond conventional lubrication practices. With its ability to enhance heat dissipation during machining processes, this technique contributes to extended tool life and reduced wear on cutting tools. Additionally, minimal quantity lubrication promotes cleaner working environments by minimizing airborne oil mist typically associated with flood cooling methods. This reduction in hazardous emissions not only improves worker safety but also simplifies maintenance procedures.

Conclusion: Embracing the Future of Lubrication Efficiency

Pioneering Sustainable Manufacturing Practices through MQL Implementation

As industries strive for greater efficiency and sustainability, embracing minimal quantity lubrication techniques is a logical step forward. By optimizing lubricant application, reducing waste, and enhancing machining performance, MQL offers a promising future for manufacturing practices. With its ability to deliver precise quantities of lubricant directly to the contact zone between tool and workpiece, this innovative approach revolutionizes traditional methods while promoting environmental responsibility. Let us embark on this journey towards sustainable manufacturing together by harnessing the power of minimal quantity lubrication!