Tolerance selection plays a critical role in CNC machining, especially for projects involving precision molds and tooling components. While drawings often specify numerical limits, the real difference between tight tolerance and standard tolerance CNC parts lies in how those limits affect functionality, production strategy, and long-term reliability. In mold manufacturing, tolerances directly influence alignment accuracy, wear behavior, and part interchangeability. When sourcing components through a CNC machining service in China, understanding these distinctions helps engineers and buyers communicate requirements more clearly and avoid unnecessary complexity. Manufacturers such as Livepoint Tooling are typically involved in these discussions not as decision-makers, but as technical partners who translate design intent into practical machining solutions.

Tight Tolerance CNC Parts and Functional Accuracy in Molds

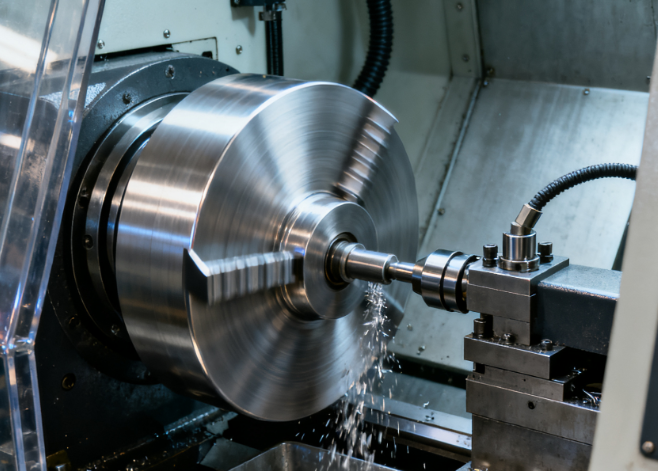

Tight tolerance CNC parts are designed with very narrow dimensional allowances, often required for components that directly affect mold precision. In injection mold applications, these parts may include cavity inserts, core pins, ejector sleeves, or cylindrical features that must maintain exact alignment during repeated cycles. The purpose of tight tolerance is functional necessity rather than preference, as even minimal deviation may lead to uneven wear, flashing, or difficulty during assembly. Producing such components requires stable machining processes, careful toolpath planning, and consistent inspection routines. Many experienced CNC machining service manufacturers emphasize process control and machining sequence optimization when working on tight tolerance features, especially in hardened materials. In this context, CNC Turning is commonly applied to achieve efficient machining of deep holes and tight-tolerance cylindrical parts, allowing suppliers to maintain dimensional consistency while meeting delivery timelines measured in days rather than extended lead times.

Standard Tolerance CNC Parts and Manufacturing Efficiency

Standard tolerance CNC parts serve a different but equally important role in mold construction. These components are typically designed with wider allowable dimensional ranges and are used where absolute precision is not critical to mold performance. Examples include mold plates, support blocks, and structural housings that provide strength and stability rather than precise alignment. Applying standard tolerance in appropriate areas helps balance manufacturing efficiency and cost control, particularly in complex mold assemblies with many components. When working with a CNC machining service in China, buyers often benefit from discussing which features truly require tight tolerance and which can be produced to standard limits without affecting performance. This distinction allows machining resources to be focused where precision delivers functional value, while reducing unnecessary processing steps on non-critical parts.

Balancing Both Tolerance Types in Practical Mold Design

In real-world mold manufacturing, tight tolerance and standard tolerance CNC parts are rarely used in isolation. Most projects combine both approaches to achieve optimal performance and manufacturability. Designers may specify tight tolerance only on mating surfaces, moving components, or sealing areas, while allowing standard tolerance elsewhere. This balanced strategy supports predictable mold behavior while controlling production cost and lead time. Suppliers with experience in tooling applications often assist in reviewing drawings to ensure tolerance choices align with actual use conditions. From a machining perspective, combining milling and CNC Turning operations allows cylindrical and rotational features to be produced efficiently without compromising accuracy. This integrated approach supports stable output while meeting the practical demands of mold assembly and maintenance.

Conclusion: Practical Tolerance Decisions for CNC Machined Mold Parts

Choosing between tight tolerance and standard tolerance CNC parts is not simply a technical preference but a functional and economic decision. Tight tolerance components support accuracy-critical mold features, while standard tolerance parts contribute to overall structure and cost efficiency. Understanding these differences helps engineers work more effectively with machining partners and prevents over-specification that adds complexity without functional benefit. In precision mold projects, tolerance decisions are most effective when guided by application needs, machining capability, and long-term reliability considerations. By aligning design intent with realistic manufacturing practices, CNC machining becomes a reliable support process rather than a limiting factor in mold performance.