In the realm of machining, a groundbreaking innovation has emerged – the Double-Sided Milling Cutter. This cutting-edge tool not only guarantees long-term accuracy but also boasts exceptional efficiency, propelling manufacturing processes to unprecedented heights. With its dual-faced design and advanced engineering, this remarkable creation is set to redefine the boundaries of precision machining.

A New Era in Machining: The Birth of Dual-Faced Excellence

Gone are the days when machinists had to compromise between accuracy and productivity. The advent of the Double-Sided Milling Cutter heralds a new era where both these crucial aspects can be achieved simultaneously with unparalleled finesse. By harnessing state-of-the-art technology and leveraging years of expertise, this revolutionary tool offers an unrivaled solution for manufacturers seeking optimal results.

The secret behind its extraordinary performance lies in its unique dual-faced construction. Unlike traditional milling cutters that operate on one side only, this innovative marvel features two cutting edges meticulously engineered to perfection. This ingenious design allows for simultaneous double-sided milling operations, drastically reducing production time while maintaining impeccable precision throughout.

Furthermore, meticulous attention has been paid to every aspect of this masterpiece’s development process. From selecting high-grade materials known for their durability and wear resistance to employing advanced coating techniques that enhance longevity – no stone has been left unturned in ensuring utmost reliability even under demanding conditions.

Precision Perfected: Achieving Impeccable Accuracy

When it comes to achieving long-term accuracy without compromising efficiency, the Double-Sided Milling Cutter stands head and shoulders above its counterparts. Equipped with ultra-precise cutting geometries meticulously crafted through rigorous testing protocols, this formidable tool delivers flawless results time after time.

Moreover, the incorporation of advanced stabilization mechanisms guarantees minimal vibration during operation, further enhancing precision. This groundbreaking feature ensures that even the most intricate and delicate machining tasks can be executed with utmost accuracy, leaving no room for errors or deviations.

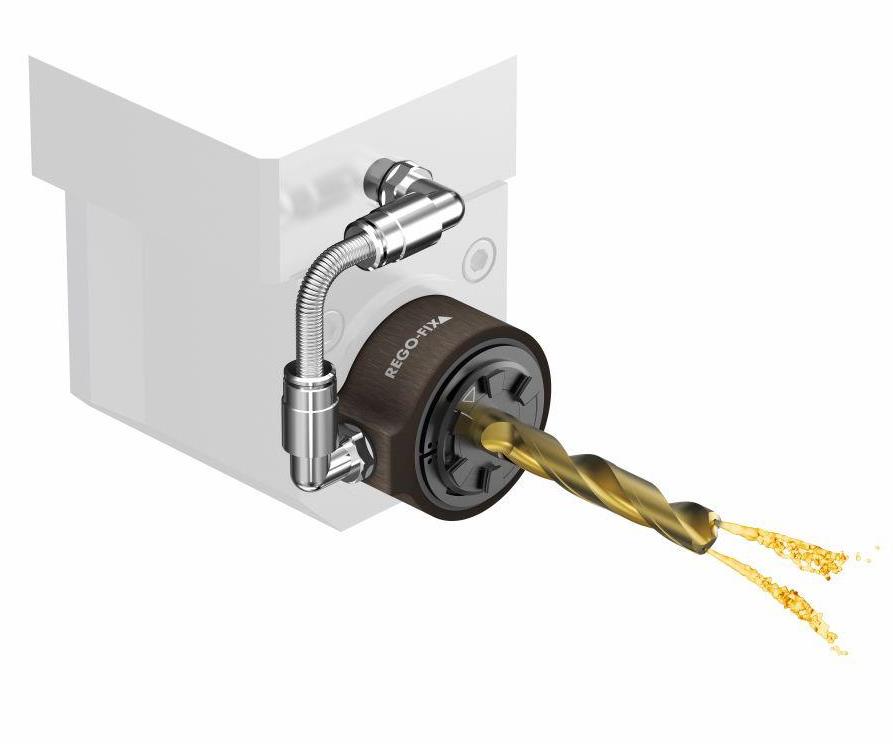

Additionally, a cutting-edge chip evacuation system has been integrated into this marvel to prevent chip accumulation and subsequent tool damage. By effectively removing chips from both sides of the milling process, uninterrupted operations are ensured while maintaining optimal performance throughout extended production runs.

The Future Unveiled: A Paradigm Shift in Manufacturing

The advent of the Double-Sided Milling Cutter marks a significant turning point in the manufacturing landscape. With its ability to achieve long-term accuracy alongside exceptional efficiency, this game-changing tool empowers manufacturers to push boundaries and unlock new realms of productivity.

In an industry where precision is paramount and every second counts, embracing this revolutionary technology becomes imperative for those seeking a competitive edge. As we witness traditional limitations crumble before our eyes, it is evident that the future belongs to those who dare to embrace innovation – those who harness the power of dual-faced excellence offered by this remarkable creation.

Achieving Perfection: The Dual-Faced Legacy

In conclusion, the Double-Sided Milling Cutter emerges as an unrivaled force in modern machining. Its dual-faced design revolutionizes conventional practices by delivering impeccable accuracy without compromising on efficiency. As manufacturers strive for perfection in their processes, embracing this extraordinary tool becomes not just an option but a necessity – one that paves the way towards unparalleled success in today’s fiercely competitive industrial landscape.