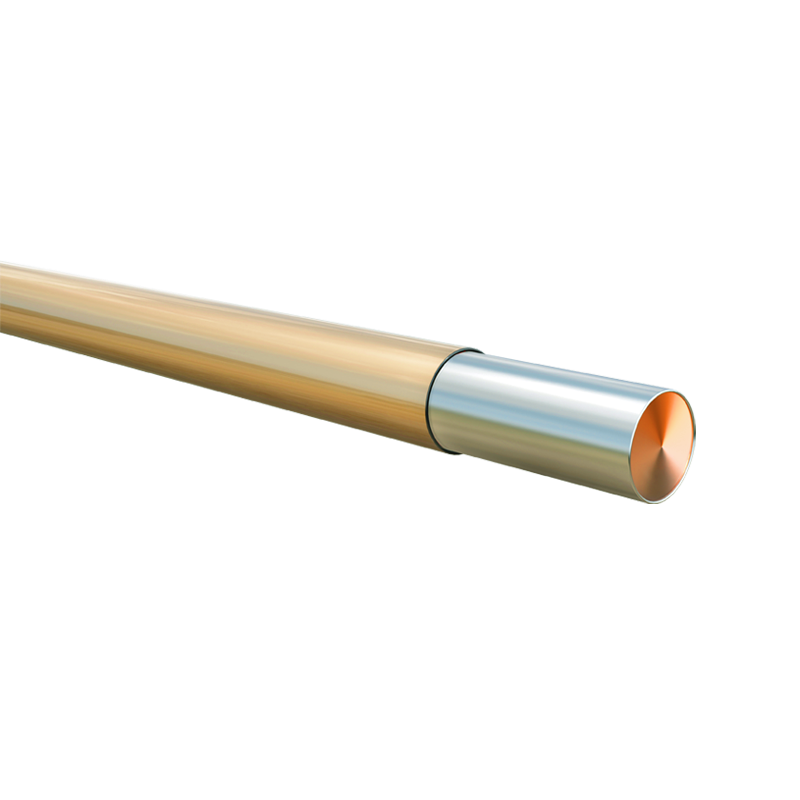

jMedtech stands out as a leader in the production of PTFE catheter liners, particularly with its MorphoLiner™ Casted OTW PTFE Liner. This innovative product exemplifies the company’s commitment to consistency and quality in thin wall medical tubing.

Controlled Production Process

The MorphoLiner™ is manufactured using a controlled Dip Coating process, which is pivotal for maintaining production consistency. Each stage of this process adheres to rigorous standards, ensuring that every PTFE catheter liner exhibits uniformity and reliability. This meticulous approach not only produces high-quality components but also supports the development of advanced medical devices. As a result, manufacturers can trust that the thin wall medical tubing they use will perform consistently across various applications.

Commitment to Quality Assurance

Quality assurance is integral to the manufacturing of the MorphoLiner™. Produced in ISO 13485-certified cleanrooms, these PTFE catheter liners comply with stringent biocompatibility requirements essential for medical devices. jMedtech employs state-of-the-art equipment and precise measurement systems to guarantee consistent product quality and performance. This level of quality assurance ensures that the MorphoLiner™ not only meets but exceeds industry expectations, ultimately enhancing the safety and effectiveness of medical devices.

In conclusion, the MorphoLiner™ Casted OTW PTFE Liner exemplifies jMedtech’s dedication to production consistency and quality assurance in the realm of thin wall medical tubing. By combining advanced manufacturing processes with rigorous quality control, jMedtech provides reliable solutions that contribute significantly to the medical device industry, ensuring better outcomes for patients and healthcare providers alike.