In the fast-evolving market for hygiene products, businesses increasingly seek reliable manufacturing solutions for their wet wipes. One such option that has gained traction is the wholesale wet wipe production line, particularly those offered by reputable brands like ZLINK. This article will delve into the expected lifespan of a quality wet wipes production line, with a focus on the automatic wet wipes machine.

Factors Influencing Lifespan

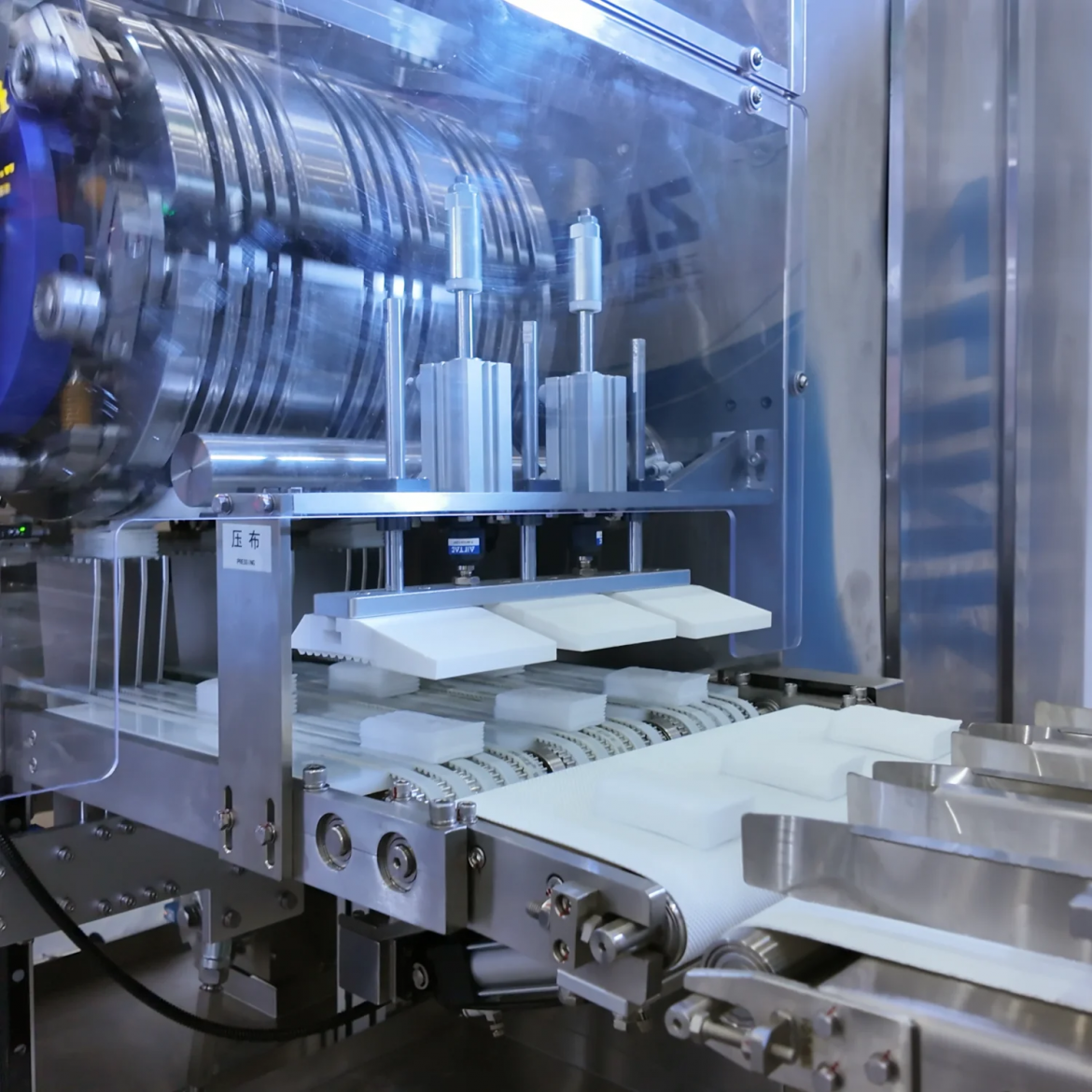

The expected lifespan of a wet wipes production line can vary significantly based on several factors. First, the build quality of the machinery plays a crucial role. High-quality equipment, such as the WE-SF2 SUPERMINI 3D PACKING WIPES PRODUCTION LINE from ZLINK, is designed for durability and efficiency. This model provides advanced features that exceed traditional semi-automatic lines, ensuring a longer operational lifespan.

Regular maintenance also impacts longevity. Businesses that invest time and resources in routine checks and servicing can extend the lifespan of their production line considerably. Proper lubrication, timely replacement of worn parts, and adherence to operational guidelines can prevent breakdowns and enhance the overall efficiency of the automatic wet wipes machine.

Moreover, environmental conditions in which the machinery operates must be considered. Wet wipes production involves moisture, and thus, a climate-controlled environment can help mitigate rust and degradation of components, prolonging the life of the equipment.

The Role of Technology

Advancements in technology have further enhanced the expected lifespan of modern wet wipes production lines. The WE-SF2 model’s innovative design not only facilitates a more sanitary process but also improves speed and product appearance. Unlike traditional methods, the automation in these machines reduces the risk of human error, thus ensuring consistency and reliability in production.

Automated systems are particularly beneficial in today’s market, where demand fluctuates rapidly. They can adapt to varying production needs without compromising on quality or increasing labor costs, making them an ideal choice for businesses looking to optimize their operations. The efficiency of these automatic wet wipes machines means fewer breakdowns and less downtime, contributing to a longer overall lifespan.

Ensuring Sustainability in Production

As businesses invest in a wholesale wet wipe production line, they should also consider sustainability. Choosing equipment that ensures minimal waste and energy-efficient operations can lead to reduced operational costs over time. Investing in quality machines such as those from ZLINK not only addresses the immediate need for reliable production but also supports long-term sustainability goals.

Lifespan Considerations for Your Production Line

In summary, the expected lifespan of a quality wet wipes production line hinges on equipment quality, maintenance practices, and technological advancements. Adopting an automatic wet wipes machine, such as ZLINK’s WE-SF2, can significantly enhance production capabilities while ensuring durability. As the market for wet wipes continues to grow, understanding these factors will help businesses make informed decisions about their production processes, ultimately leading to greater operational longevity and success.