Devices supplied by Juxin (Anhui Juxin Intelligent Manufacturing Technology Co., Ltd.) are crucial in the last phases of production. In order to guarantee that items are defect-free before they are sent, it is common practice to use sophisticated wire testing equipment. Having a high-tech cable wire tester oversee this procedure is crucial for preserving the reliability of products, gaining customer confidence, and preserving the reputation of brands in this cutthroat sector.

Ensuring Flawless Surface Quality

The exterior condition of a wire is the first indicator of its quality. Juxin’s Wire Surface Detector is a form of high-performance wire testing equipment designed for this specific purpose. This automated system conducts real-time monitoring to ensure flawless surface quality throughout the wire and cable production process. The cable wire tester is engineered for simple setup, allowing for seamless integration into existing production lines to provide continuous, reliable inspection without complicating operations.

Identifying Subsurface Micro-Defects

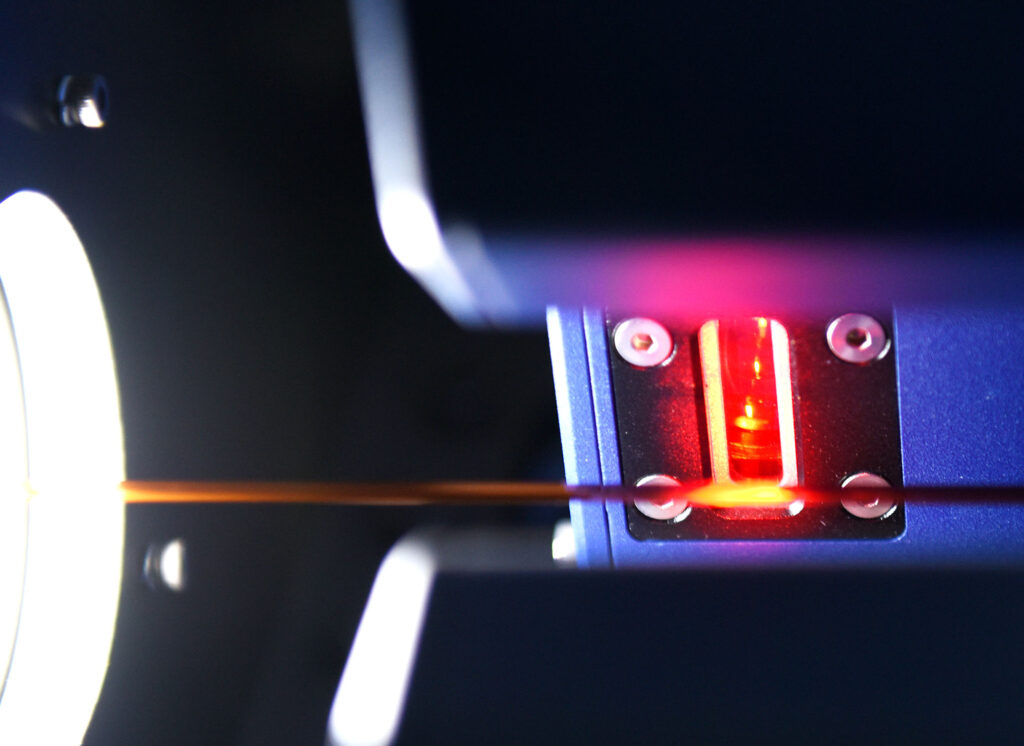

Some critical flaws are not visible to the naked eye. The High Voltage Test Equipment, another essential piece of wire testing equipment, is designed to uncover these hidden issues. This specific cable wire tester utilizes high-voltage discharge technology to meticulously scan material surfaces. Its high-voltage electrode is engineered to accurately detect invisible micro-defects such as pinholes, cracks, and breakpoints within a wire’s insulation or coating layers, preventing potential failures.

Safeguarding Product Integrity Across Industries

The utility of this technology extends beyond basic wire production. This type of rigorous wire testing equipment is widely applied in various sectors that rely on coated products, including films and tubing. The comprehensive analysis provided by a robust cable wire tester ensures that only products meeting the highest standards of safety and performance reach the market. This widespread application underscores the critical role that such diagnostic tools play in industrial quality assurance.

In summary, the commitment to quality in wire manufacturing is upheld by precise diagnostic tools. Juxin’s range of wire testing equipment, from surface detectors to high-voltage testers, provides a multi-layered approach to quality control. The function of a cable wire tester is therefore not merely a final step but a fundamental component of the production process, ensuring that every product performs as intended and adheres to stringent industry requirements.